Lean is the concept of driving manufacturing operations efficiently that evolved out of the Toyota Production System in the mid 20th century. It is based on the philosophy of defining value from the perspective of the customer, and continually improving the way in which value is delivered, by eliminating wasteful use of resources, or that does not contribute to the value as perceived by the customer.

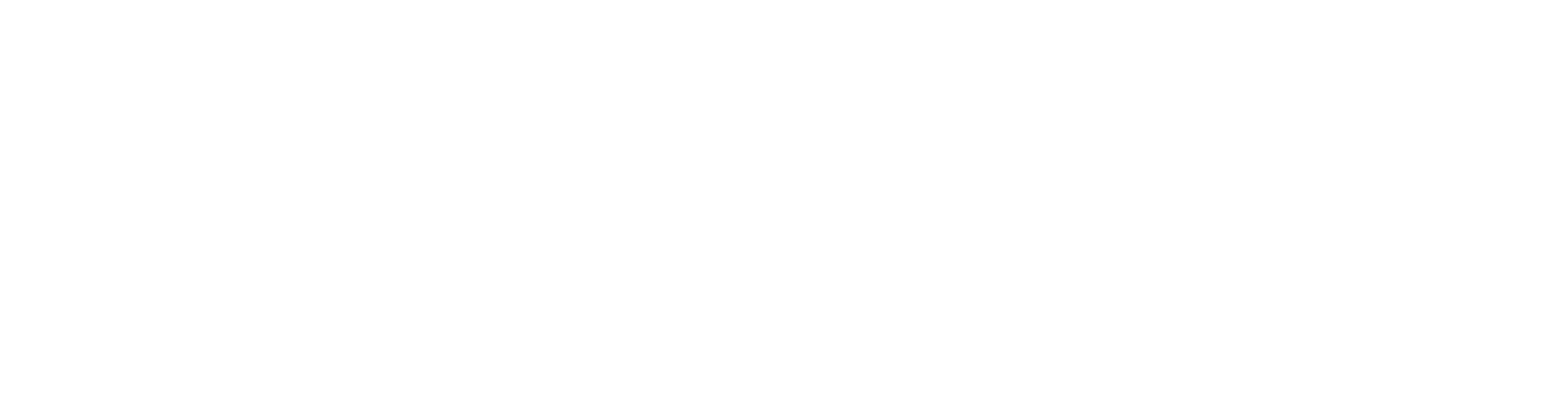

This is the visual depiction of the tools and techniques that make up the Toyota Production System.

As TPS progressed in the west they called it lean. So lean is TPS and TPS is Lean.

These tools in the House of Toyota form the Lean philosophy. Eliminating waste is the core. Waste is anything that the client is not going to pay money for. The key intent of Lean is therefore to eliminate waste. As Lean evolved waste was expanded to deviations. And Lean is therefore now a philosophy to eliminate three types of deviation MUDA (Wastefulness, uselessness), MURA (Unevenness, non-uniformity), MURI (Overburden, excessiveness)

Lean took shape from manufacturing practices but in recent time has transformed the world of all operations. It encourages the philosophy of continuous improvement and is based on the fundamental idea of the value of individuals.

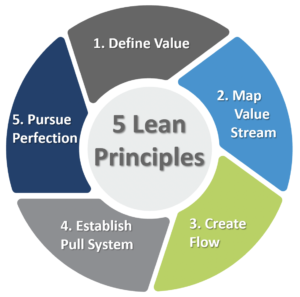

Womack and Jones have laid out the five principles of Lean manufacturing in their book “The Machine That Changed the World”.

The five principles are considered essential for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection.

The Lean philosophy provides a framework for creating an efficient and effective organization. Lean allows managers to discover inefficiencies in their organization and deliver better value to customers.

The principles encourage creating better flow in work processes and developing a continuous improvement culture.

By implementation of Lean Manufacturing an organization can remain competitive, improve the value delivered to the customers, optimize costs of its operations, and thereby increase its profitability.